CardLine -Casing Inspection

Our software was rigorously tested and proven to be superior to MipsPro, Wiva/Wiper, etc. for casing evaluation. In addition, we developed a powerful 3D viewer that allows multiple views (internal, external, 2D, etc.) It is one of the best interpretation packages on the world market, reducing interpretation time by over 75%.

The software exports a clear and concise report and a log that meets AER D-51 reporting for casing integrity. The package also combines both caliper and thickness measurements, including Class 1-5 defects with colour bars, the locations of defects, type of defect (internal/external), all in a simple to understand log plot that is easily exported in pdf format.

Caliper

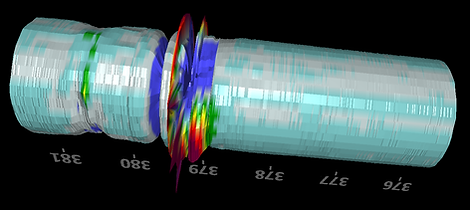

CardLine casing inspection software processes any Caliper-tool data to assess the corrosion level inside the well. Built on unique mathematical algorithms our software surpasses any known competitors in this field. To process one well our software only takes 15-20 minutes while our competitors will take 5-7 hours.

Benefits:

-

Fast processing time: 15-20 minutes per well

-

Automatically define and easily edit collar positions

-

Generate express joint summary

-

Powerful Log Viewer

-

One-click filtering and centralization

-

Create fully customizable PDF reports

-

Create printable 3D STL models

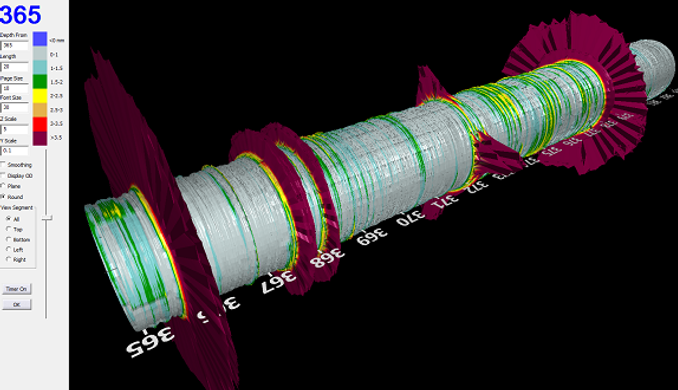

MFL

CardLine casing inspection software is now is able to process and visualize Magnetic Flux Leakage data to determine levels of corrosion inside and outside the well. Built on unique mathematical algorithms our software surpasses any known competitors in this field. To process one well our software only takes 15-20 minutes while our competitors will take 5-7 hour.

Benefits:

-

Fast processing time: 15-20 minutes per well

-

Automatically define and easily edit collar positions

-

Generate express joint summary

-

Powerful Log Viewer

-

One-click filtering and centralization

-

Create fully customizable PDF reports

-

Create printable 3D STL models

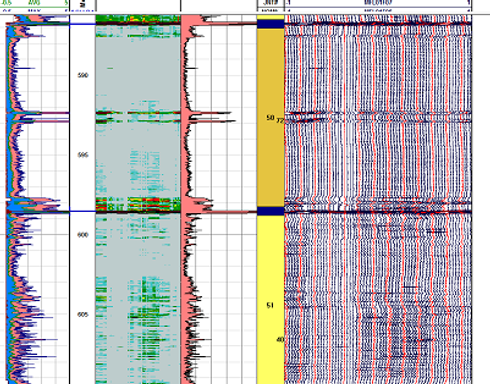

MTT

Cardgio Inc has developed a new way of performing Magnetic Tool Thickness (MTT) processing that saves our customer thousands of dollars and numerous wasted hours. Each time MTT surveying occurs the MTT tool has to be calibrated, resulting in numerous surveying stops along the well. Our software combines mathematical algorithms with Caliper data to eliminate the need of MTT calibration during the surveying. The final result is that we achieve the same outcome as with the regular calibration method, but our method saves time and provided significant savings.